Design Notes

VITROHM offers a range of low-ohm resistors for current sensing applications, resistance ranges typically from 1 milliohm to 100 milliohms.

These devices are of non-wound construction and made from flat resistive alloy wire.

The resistor‘s specification depends on the material and the chosen dimensions, namely specific-resistance, thermal conductivity and temperature coefficient are of importance.

1. Standard, leaded types, KN-family

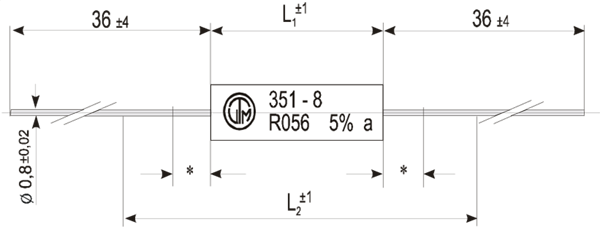

Types KN 350 ... KN 354

The „KN resistors” are available in standardized sizes with choices of open-frame and ceramic cased types. Copper leads are welded to the resistive element for board assembly.

Attention should be given to the following:

-

Resistance value

The value is specified over a given „measuring length“. Between the two measuring points lies the element plus some copper-wire for contact purposes. If the actual used total length of the resistor in the application differs from this specified length, the influence of the copper wire of 0.4 mΩ per centimeter must be considered.

- Temperature coefficient

Typically the temperature coefficient of the resistive element ranges around 150 ppm/ºC (ask factory for details). However, the copper wire is part of the effective resistance and influences the TC between the contacts.The lower the resistance value, the more influence of the copper leads, the higher the TC! If the TC is of concern in a given application, a vertical style of the KN-family should be used (type 35X-009). In this case the influence of the copper wire is almost eliminated.

- Power and current rating

The „KN-resistors “are standard products with a fixed given power rating (P70). Nevertheless, current rating can be of concern, especially if overload or pulse conditions can occur. The current limit is defined by the current density, and 100 A per mm2 are considered absolute maximum in power electronics. With a 0,8 mm diameter copper wire, the current limit is 50 A. With respect to reliability, the welding junction between copper and resistive alloy should not carry more than 20 A continuously. The 50 A limit may not be exceeded even under pulse conditions.

2. Semi-customized types, LPS-family

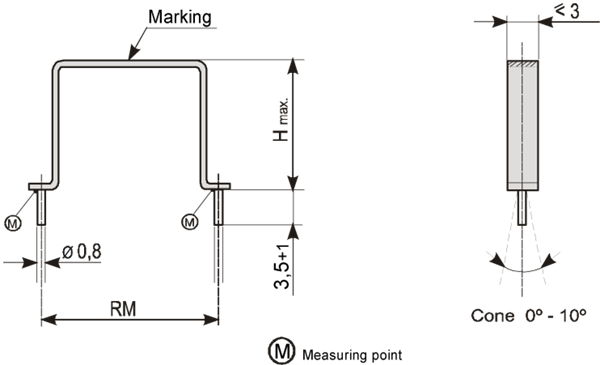

Types LPS 355 ... LPS 359

VITROHM provides tools to produce U-shaped low-ohm resistors for direct board mounting. The solder-tags (1 or 2 per side) are of given dimensions, the size of the final unit is designed in accordance with the applicational requirements. If the demand for a shunt-resistor justifies a customized solution, the LPS-family offers a variety of possibilities. The dimensions of the part are ruled by the requested power rating, as the generated heat needs to be dissipated by an appropriate surface area. To remain within reasonable size-limits, LPS-resistors are made up to 8 W rated power.

Normally, the user defines the resistance value (1 mΩ to 60 mΩ) the requested power and size limitations,if any. According to this, VITROHM designs the part.

Again, attention must be given to some facts:

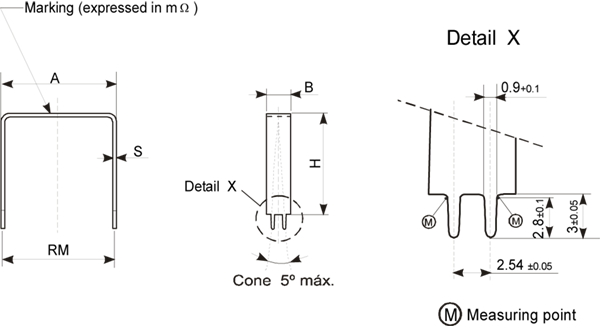

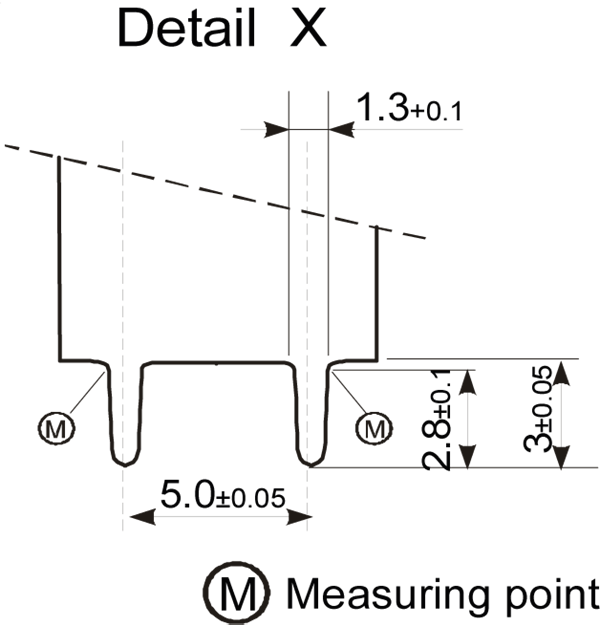

- Solder tags

The parts can be manufactured with 2 or 4 solder tags. 4 are used either for Kelvin-connections or for high current applications. Depending from the material‘s thickness, one solder contact can carry up to 70A, so a 4-contact part can carry 140A (ask factory).

However, the solder-tag represents a significant resistance if not embedded totally in solder!

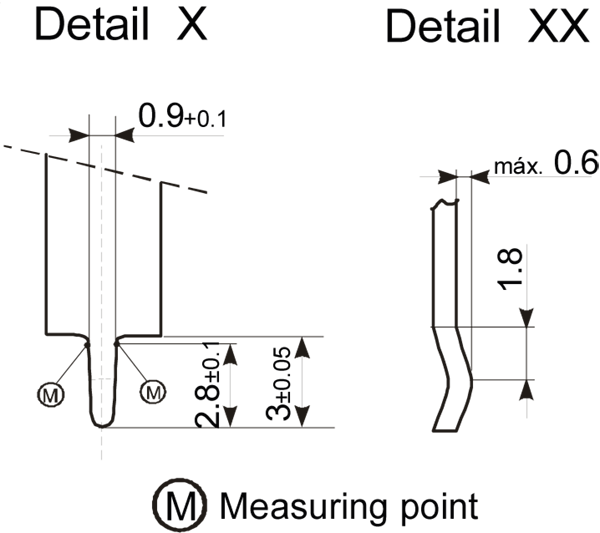

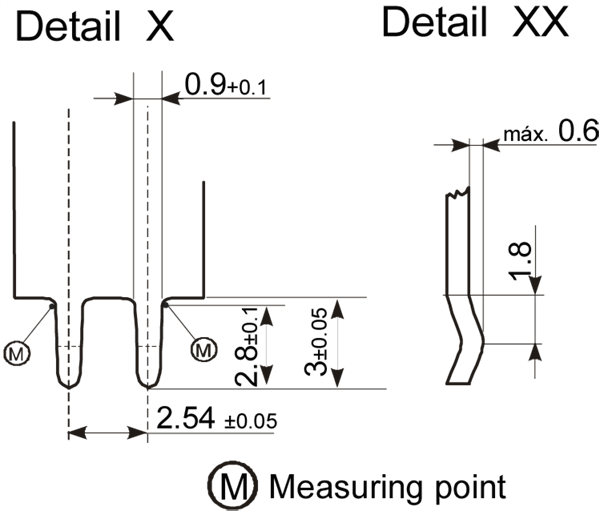

1. Standard pins: LPS 359-0XX

2. Special for low ohms: LPS 359-1XX

Utmost care must be given during assembly and board soldering, otherwise resistance value will be above specification and overheating at solder joint may occur.

- Solderability

Solder tags are made from resistive alloy to avoid falsification of temperature coefficient. Solderability is enhanced by special chemical cleaning of the surface after production and is preserved by special packing in nitrogen atmosphere. Nevertheless, in cases, soldering parameters (temperature, time) must be adjusted for good results, as the LPS-resistor acts like a heat-sink during soldering.

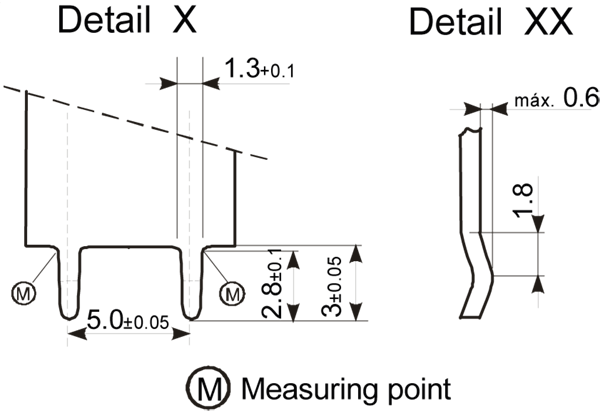

Depending on value and power rating, 6 different solder tags are available:

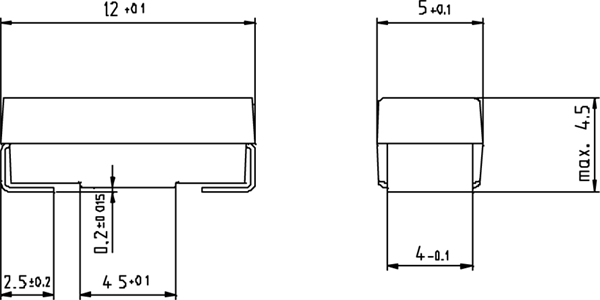

3. Special for very low ohm and high power: LPS 359-2XX

4. Same as LPS 359-0xx, but with a snap in: LPS359-3XX

5. Same as LPS 359-1XX, but with a snap in: LPS 359-4XX

Special varieties on request.

RM: Available from 5 to 25 mm, preferably in 5 mm-steps.

H, B and S depend on material, resistance value and required rating.

6. Same as LPS 359-2XX, but with snap in: LPS359-5XX

3. Low-Power,moulded type, RWN family:

If power rating is not the main concern, i.e. current ranges below 5A, a current sensing device in a standard resistor package may be suitable.

VITROHM offers a SMD-version (RWN). It is designed for automatic PCB-assembly in blister-tape (RWN).

The power rating for this type is limited by the max. temperature of the moulding material. Overheating may cause carbonizing of the plastic, short circuit may occur. This limits also the pulse handling capacity. 40A can be carried by the internal contacts, but energy must not exceed 625 mWs.

VITROHM has the products and the knowledge.

If you need help in designing - in the right product or need more information, please contact your sales contact for assistance.